Non-Conformance: Definition, Types, Examples, and Tips

- Robert Jakobson

- Aug 27, 2024

- 14 min read

Updated: Nov 20, 2024

What is Non-Conformance?

Non-conformance is a term that might sound complicated, but it’s actually quite simple. It just means that something isn’t right — it doesn’t meet the rules or standards it’s supposed to.

In food production, non-conformance happens when a product, process, or even a piece of equipment doesn’t meet the standards or rules it’s supposed to. This could mean anything from a product being unsafe to eat, to a machine not working correctly, or even paperwork not being filled out properly. Maybe the product didn’t pass a quality check, or perhaps a machine wasn’t cleaned properly before use.

Table of Contents

Why non-conformance matters

Why is it so important to understand non-conformance? Well, when you’re producing food, at an industrial scale, there are a lot of rules and standards you have to follow, like BRCGS or GFSI standards, to make sure the food is safe to eat. If something doesn’t meet these standards, it can cause big problems.

Every day, your entire company works hard to make sure everything is done right, from making sure machines are clean to checking that ingredients are safe. But one day, during a regular inspection, something goes wrong. Maybe a batch of food doesn’t meet the safety standards, or maybe a piece of equipment isn’t working as it should. What happens next?

For example, if a product isn’t safe, it might have to be recalled, which means taking it off the shelves and telling people not to eat it. This can cost a lot of money and hurt the company’s reputation. But more importantly, it could make people sick.

A quick example of non-conformance

Let’s break it down. Imagine you’re making a batch of cookies in a big factory. The recipe says you need to bake them at 350°F for 15 minutes to make sure they are cooked properly and safe to eat. But what if the oven is set to the wrong temperature?

Or what if the cookies are taken out too early? This would be an example of non-conformance because the cookies wouldn’t meet the safety and quality standards they’re supposed to.

Non-conformance can happen in many different ways. It could be a problem with the product itself, like ingredients that aren’t fresh or packaging that’s damaged. It could also be an issue with the process, like a machine not working right, or with the paperwork, like missing information in a report. No matter what the cause, non-conformance means that something didn’t go as planned and needs to be fixed.

Non-conformance in safety standards

In food production, there are many standards and rules that must be followed to keep food safe. These rules are set by organizations like ISO (International Organization for Standardization). You might have heard of some of these standards, like ISO 9001 or ISO 22000, which are guidelines that help companies make sure their products are safe and meet quality requirements. When a product or process doesn’t meet these guidelines, it’s considered a non-conformance.

For example, ISO 9001 is a standard that covers general quality management. It helps companies make sure that everything they do is aimed at meeting customer needs and improving their processes. If a company doesn’t follow these guidelines, they might end up with products that aren’t as good as they should be, leading to non-conformance.

ISO 22000 is another important standard, specifically for food safety. It sets rules to make sure food is safe from the farm all the way to the table. If a company fails to meet these food safety standards, it could result in food that isn’t safe to eat, which is a serious form of non-conformance.

There’s also something called GFSI (Global Food Safety Initiative), which is a global organization that sets high standards for food safety. If a company doesn’t follow these standards, they could be putting people’s health at risk.

So, in simple terms, non-conformance means that something doesn’t meet the rules or standards it’s supposed to. This could be a small issue, like a mistake in paperwork, or a big problem, like a product that isn’t safe to eat.

Detect non-conformances 90% faster with Inspectle

Inspectle Food is the best AI-powered visual inspection software for the food industry. It supports all the main food safety standards from BRCGS, GFSI, ISO 22000 to SQF.

Click below to take a quick interactive tour that shows how you can track and fix non-conformances 90% faster with our app. You can then start a free trial if you like what you see.

Different types of non-conformances

Not all non-conformances are the same. Some are more serious than others, and understanding the types of non-conformance can help you figure out how to deal with them.

Major Non-Conformance

Let’s start with major non-conformance. This is when something goes seriously wrong. It’s a big deal because it can directly impact the safety, legality, or quality of the food product.

For example, if a batch of canned soup is found to have bacteria in it, this is a major non-conformance. The soup could make people sick, so it has to be dealt with immediately.

Major non-conformances can lead to product recalls, where the company has to take the product off the shelves and tell people not to use it. This can be very costly, not just in terms of money but also in terms of the company’s reputation. People might lose trust in the brand, and it can take a long time to rebuild that trust.

Another example of major non-conformance could be if a machine that fills bottles with juice is not cleaned properly, leading to contamination. In this case, the entire production line might need to be stopped until the problem is fixed.

Minor Non-Conformance

Now, let’s talk about minor non-conformance. These are smaller issues that don’t have an immediate impact on safety or quality, but they still need to be corrected. For instance, if a label on a product is printed with the wrong expiration date, this would be a minor non-conformance. The food might still be safe to eat, but the incorrect label could confuse customers and cause problems down the line.

Minor non-conformances are often easier to fix and might not require as much attention as major non-conformances. However, if minor issues are ignored or not dealt with properly, they can build up and lead to bigger problems. It’s like letting a small leak in a boat go unnoticed—it might seem harmless at first, but over time, it could sink the whole ship.

Critical Non-Conformance

Lastly, there’s something called a critical non-conformance. This type happens when the same issue keeps coming up over and over again. It’s not just a one-time mistake; it’s a sign that there’s a deeper problem within the system.

For example, if every week you find that the same machine is causing problems, this might be a critical non-conformance. It means that the issue isn’t being fully fixed, and something needs to change to prevent it from happening again.

Critical non-conformance is like a red flag. It tells you that there might be a bigger issue in the way things are being done. Maybe the procedures need to be updated, or maybe the staff needs more training. Whatever the cause, it’s important to address systemic non-conformance quickly, so it doesn’t keep happening.

Why Knowing the Types Matters

Understanding the different types of non-conformance is important because it helps you figure out the best way to fix the problem.

Major non-conformances need to be dealt with immediately because they can have serious consequences.

Minor non-conformances should also be addressed, but they might not require as much urgency.

Critical non-conformances need special attention because they point to a bigger problem that could cause trouble in the future.

Non-Conformance vs. Non-Compliance

Have you ever heard the terms "non-conformance" and "non-compliance" and wondered if they mean the same thing? They might sound similar, but they actually refer to different things. Understanding the difference between them is important, especially when you’re working in food production.

What is Non-Conformance?

We’ve already talked about non-conformance, but let’s quickly recap. Non-conformance happens when something doesn’t meet the standards or rules it’s supposed to. For example, if a product doesn’t pass a quality check, or if a machine isn’t working correctly, that’s a non-conformance. It means something isn’t going according to plan, and it needs to be fixed.

Non-conformance can be something small, like a mistake on a label, or something big, like a safety issue with the product. It’s all about making sure everything is done right so that the final product is safe and of good quality.

What is Non-Compliance?

Now, let’s talk about non-compliance. Non-compliance is when something doesn’t follow the rules or laws that are set by outside organizations, like the government or industry standards. For example, if a food company is supposed to follow certain food safety regulations and doesn’t, that’s non-compliance. It’s a more serious issue because it means the company isn’t following the law.

Say, you’re driving a car, and the speed limit is 30 miles per hour. If you drive at 40 miles per hour, you’re breaking the law—you’re not complying with the speed limit.

In the same way, if a company doesn’t follow food safety regulations, they’re not complying with the law, which can lead to fines, legal trouble, or even being shut down.

How Are They Different?

The main difference between non-conformance and non-compliance is where the rules come from. Non-conformance is about not meeting the standards or guidelines that the company has set for itself or that are expected in the industry. Non-compliance, on the other hand, is about not following the rules set by external authorities, like the government or certification bodies like the FDA.

For example, if a company decides that all workers must wear hairnets in the factory, and someone forgets to put one on, that’s non-conformance.

The company has its own rules, and the worker didn’t follow them. But if the company doesn’t follow a government regulation, like not properly labeling allergens on food products, that’s non-compliance. It’s breaking the law, which can have much bigger consequences.

Why Does the Difference Matter?

Understanding the difference between non-conformance and non-compliance is important because it helps you know how to handle problems when they come up.

If something is a non-conformance, it might just need a simple fix, like retraining a worker or adjusting a process. But if something is a non-compliance issue, it could mean serious trouble, like fines or legal action, and it needs to be addressed immediately.

For example, if a company finds out that they haven’t been following a food safety regulation, they need to fix the problem right away to avoid legal consequences. This might mean changing their processes, training their staff, or even recalling products that have already been shipped out.

On the other hand, if the issue is a non-conformance, like a minor mistake in a production process, the company might not face legal consequences, but they still need to fix it to make sure the product is safe and meets the company’s standards.

Working Together to Fix Problems

In many cases, non-conformance and non-compliance can be related. If a company consistently has non-conformance issues, it might eventually lead to non-compliance if those issues aren’t fixed. For example, if a company regularly has problems with labeling products correctly (a non-conformance), it could eventually result in breaking labeling laws (non-compliance).

This is why it’s so important to catch and fix non-conformance issues early. By keeping everything up to standard, a company can avoid the bigger problems that come with non-compliance.

Understanding the difference between these two concepts can help you take the right steps to fix problems and keep your food production process safe and smooth.

Common examples of non-conformances

Think about the last time you bought a snack or a drink. You probably didn’t worry about whether it was safe to eat or drink. That’s because there are many rules and standards in place to make sure food is safe before it gets to you. But what happens when something goes wrong during production? That’s where non-conformance comes in. Let’s look at some common examples of non-conformance in food production and what can be done to fix them.

Example 1: Contaminated Ingredients

One of the most serious types of non-conformance is when food products become contaminated. Contamination can happen in many ways. For example, if raw ingredients like fruits or vegetables aren’t washed properly before they’re used, they might carry bacteria that can make people sick. This is a major non-conformance because it directly affects the safety of the food.

Another example could be if a piece of equipment isn’t cleaned properly between batches, and leftover food particles get into the next batch. This can cause cross-contamination, especially if the leftover food contains allergens like peanuts or gluten. For someone with a food allergy, this could be very dangerous.

When contamination is discovered, it’s important to act quickly. The contaminated product must be separated from the rest and properly disposed of. The equipment must be thoroughly cleaned and sanitized before it can be used again. Sometimes, the entire production line may need to be shut down until the issue is resolved. This helps prevent any unsafe products from reaching customers.

Example 2: Incorrect Labeling

Imagine buying a box of cereal and later finding out that it contains nuts, even though the label didn’t say so. This is an example of incorrect labeling, which is another common type of non-conformance. Labeling mistakes can happen in many ways. Maybe the wrong label was put on the product, or maybe important information, like the ingredients or expiration date, was left off the label.

Incorrect labeling can cause a lot of problems, especially for people with food allergies or dietary restrictions. If someone with a peanut allergy eats something that wasn’t labeled correctly, it could lead to a serious allergic reaction. That’s why it’s so important to get labeling right.

To fix incorrect labeling, the company usually has to recall the product from stores. This means they have to take the product off the shelves and tell people not to eat it. The company also needs to figure out how the mistake happened so they can prevent it from happening again. This might involve double-checking labels before they’re applied or improving the system that tracks which labels go on which products.

Example 3: Equipment Malfunctions

Another common example of non-conformance is when equipment in the production line malfunctions. For instance, a machine that’s supposed to measure out ingredients might not be working right, leading to too much or too little of an ingredient being added. This can affect the taste, texture, and safety of the final product.

Equipment malfunctions can happen for many reasons. Maybe the machine wasn’t properly maintained, or maybe it wasn’t set up correctly. Whatever the cause, it’s important to identify and fix the problem as soon as possible.

If a malfunctioning machine is discovered, the production line might need to be stopped until the issue is fixed. The affected products may need to be checked or even discarded if they don’t meet quality standards. After the machine is repaired, it should be tested to make sure it’s working correctly before production starts again.

Example 4: Incomplete Documentation

In food production, keeping accurate records is very important. These records help track everything from the ingredients used to the steps taken during production. If these records are incomplete or missing, it’s considered a non-conformance.

Incomplete documentation can cause a lot of problems, especially if there’s an issue with a product. Without proper records, it’s hard to trace back and find out where things went wrong. For example, if a batch of food is found to be unsafe, accurate records are needed to figure out what caused the problem and how to fix it.

To avoid this type of non-conformance, it’s important to make sure that all steps in the production process are properly recorded. This includes everything from the source of ingredients to the cleaning of equipment. If a mistake is found in the documentation, it should be corrected right away, and the person responsible should be trained on the proper procedures.

Why Address Non-Conformances?

When non-conformance occurs, it’s like a warning sign that something isn’t right. If ignored, even a small problem can turn into a big issue. For example, a small mistake in labeling might seem harmless, but if left uncorrected, it could lead to a serious situation where customers are misled, or worse, put at risk.

Addressing non-conformance is important for several reasons:

Safety: The most important reason is safety. Food products that don’t meet safety standards can make people sick. If a batch of food is contaminated, it needs to be identified and removed quickly to prevent anyone from getting hurt.

Quality: Non-conformance can also affect the quality of your products. For instance, if a machine isn’t working properly, the products it makes might not taste or look the way they’re supposed to. Addressing the issue ensures that the products you produce are consistent and of high quality.

Compliance: Many food production companies have to follow strict rules and regulations. If a company doesn’t address non-conformance, it could lead to non-compliance with these rules, resulting in fines, legal trouble, or even the loss of certification. This is why it’s important to catch and fix non-conformance before it leads to bigger problems.

Reputation: A company’s reputation is built on trust. If customers find out that a company’s products aren’t safe or don’t meet the promised standards, they might stop buying those products. Addressing non-conformance quickly helps maintain the trust that customers have in your brand.

Cost Savings: Fixing a small problem now can save a lot of money later. If non-conformance is ignored, it could lead to a product recall, where the company has to take products off the shelves and possibly pay fines or compensation. By addressing non-conformance early, you can avoid these costs.

How to Use Inspectle to Fix Non-Conformances

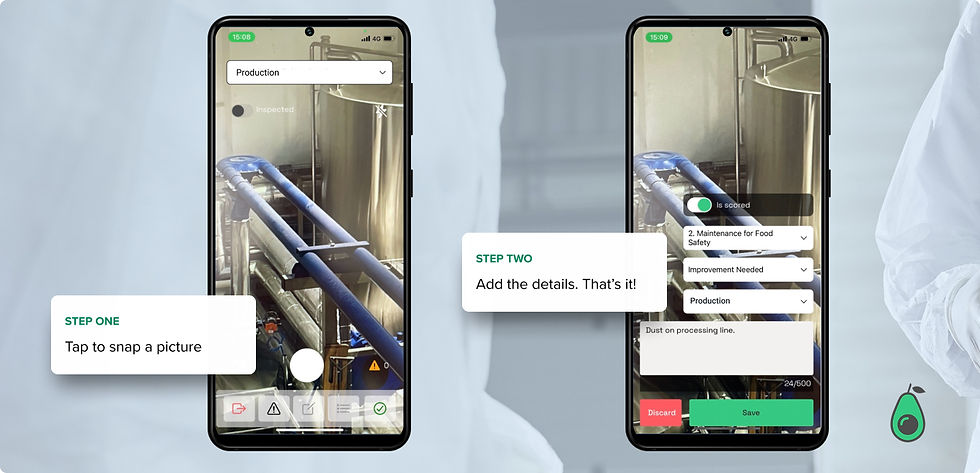

When a non-conformance happens, it’s important to act quickly and efficiently to fix the problem. Inspectle makes this process easier by focusing on visual inspections and images as proof to document, and resolve issues.

Here’s how you can use Inspectle to address non-conformances step by step:

1. Identify the Problem

The first step is to recognize that there is a problem. With Inspectle, this can be done by giving your team members who do inspections access to the Inspectle mobile app.

You can get access by starting a free trial here.

Regardless if you only want select few people to do inspections or want to involve a larger team, Inspectle is designed to catch non-conformances early.

For example, during an inspection, if an employee notices something wrong, like a broken piece of equipment or a product that doesn’t meet quality standards, they can immediately document the issue by taking out their phone and snapping a picture.

2. Document the Issue

Once the problem is identified, the next step is to document it. Inspectle makes this simple.

The employee can use the app to add a description, and record where and when the issue was found. Most importantly, they can assign it the right category of non-conformance according to the food safety standard you follow. For that Inspectle supports BRCGS, FSSC 22000, IFS, GFSI, and ISO 22000 standards.

This documentation is automatically saved in the system, making it easy to track and manage. With Inspectle, every detail is captured in real-time, ensuring nothing is overlooked.

3. Investigate the Cause

After documenting the issue, the next step is to find out why it happened. Inspectle helps with this too. You can review the inspection history and any related reports to see if this problem has happened before.

This can help identify patterns or recurring issues, giving you clues about the root cause.

Whether it’s a process that needs adjusting or equipment that requires maintenance, Inspectle provides the information you need to make informed decisions.

4. Take Corrective Action

Once you understand what caused the problem, it’s time to take action. Inspectle allows you to assign tasks directly through the app.

For example, if a machine needs to be repaired, you can assign the task to the maintenance team with all the necessary details, including photos and location. Inspectle tracks these tasks, so you can see when the problem is resolved and who was responsible for fixing it. This ensures that corrective actions are taken quickly and effectively.

5. Follow Up

After taking corrective action, it’s important to check that the problem has been fully resolved. Based on how many problems have been resolved and your preferred food safety standard, Inspectle will automatically calculate the corresponding hygiene index and give you additonal data and reports.

6. Prevent Future Problems

Finally, use what you’ve learned from this incident to prevent future problems. Inspectle helps by providing reports and analytics that show trends and patterns in non-conformance.

You can use this data to update processes, improve training, or even invest in new equipment if needed. By reviewing the information gathered, you can create a system that catches and corrects non-conformance before it becomes a bigger issue.

With Inspectle, addressing non-conformance becomes a straightforward. Try it for free.

About the Author: Robert Jakobson

Robert Jakobson has worked in the manufacturing industry since 2010. With over a decade of experience in B2B marketing, he specializes in helping companies improve their operations with software and hardware solutions. His deep knowledge of the industry and passion for technology make him a trusted expert. Robert’s experience ranges from product development to marketing, giving him valuable insights into how businesses can use tools like the Inspectle Food Safety Inspection software to stay compliant and improve their processes.